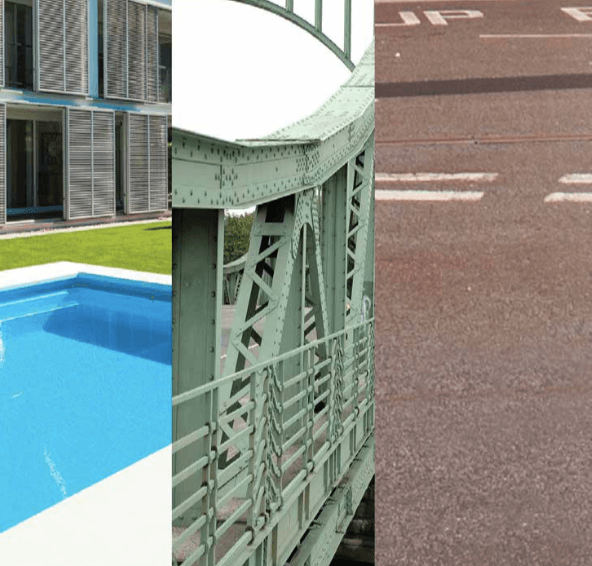

Dual component polyurethane coating product used in coatings of pools, bridges, exteriors, parking areas and marine vehicles like yachts-boats because of its’ outstanding features like non-solvent chemical, mechanical and hydrolysis resistance. Preferred for tis’ fast curing and strong bonding to surface.

PRODUCT DETAILS

Hard:

- Density (25 °C): kg/m3 1.00 (Polyol) 1.10 (Prepolymer)

- Viscosity (25 °C): cPs 350-550 (Polyol) 650-850 (Prepolymer)

- Storing temperature: °C 20-25 (Polyol) 20-25 (Prepolymer)

- Mix proportion: Hacimce 100:100 (Polyol)

- Gelling time: sec. 8-12 (Polyol)

Flexible:

- Density (25 °C): kg/m3 1.00 (Polyol) 1.10 (Prepolymer)

- Viscosity (25 °C): cPs 600-800 (Polyol) 650-850 (Prepolymer)

- Storing temperature: °C 20-25 (Polyol) 20-25 (Prepolymer)

- Mix proportion: In volume 100:100

- Gelling time: sec. 8-12

Hybrid:

- Density (25 °C): kg/m3 1.03 (Polyol) 1.11 (Prepolymer)

- Viscosity (25 °C): cPs 750-10000 (Polyol) 550-750 (Prepolymer)

- Storing temperature: °C 20-25 (Polyol) 20-25 (Prepolymer)

- Mix proportion: In volume

- Gelling time: sec. 8-10

Hard:

- Hardness: Shore A 80-85

- Stretch at break: % 500-550

- Strength at break: MPa 13-18

Flexible:

- Hardness: Shore A 92-98

- Stretch at break: % 270-320

- Strength at break: MPa 8-12

Hybrid:

- Hardness: Shore A 88-93

- Stretch at break: % 350-400

- Strength at break: MPa 5-10

Contact Form

You can use the form below to request all questions, suggestions and suggestions.